General directions for use of UA-Zero® EM Stain

UA-Zero® EM Stain is a patented solution developed as a direct replacement for Uranyl Acetate. UA-Zero does not contain any radioactive material and is non-toxic. UA-Zero can be used as a direct substitute to Uranyl Acetate with no changes to standard user protocols.

UA-Zero is supplied in an opaque dropper bottle, which should be stored long-term in the lab fridge at around 4°C. For daily use, the sealed bottle can be stored in normal laboratory conditions away from direct sunlight.

It has been shown that UA-Zero EM Stain works very well for various protocols that specify Uranyl Acetate as a staining solution for TEM sample preparation in life science. This application note describes ones example of a protocol for preparing samples and subsequent imaging using TEM. Uranyl Acetate and UA-Zero EM stain were directly compared and the images generated are shown in the Results section of this blog.

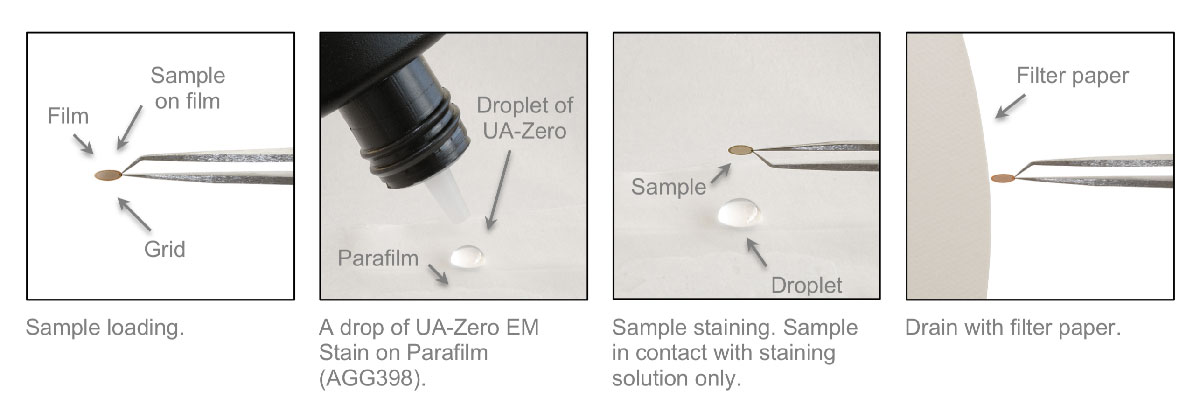

Staining the sample on a TEM grid, with a support film, requires just a few simple steps before drying.

* HeLa cells are derived from cervical cancer cells taken on February 8th, 1951 from Henrietta Lacks, nowadays being the oldest and most commonly used human cell line in scientific research.

Protocol used for TEM sample preparation

All steps performed at room temperature unless otherwise stated. Parts of the sample have been stained using UA-Zero EM Stain and Uranyl Acetate, for direct comparison.

Fixation

| 1. 2.5% glutaraldehyde (AGR1012) in 0.1M cacodylate buffer | 1 hour |

| 2. 0.1M cacodylate (AGR1105) washes | 3 x 10 mins |

| 3. 1% OsO4 (AGR1021) in 0.1M cacodylate buffer | 20 mins |

| 4. 0.1M cacodylate washes | 3 x 10 mins |

| 5. Deionised water | 3 x 10 mins |

Staining

| 6a. UA-Zero EM Stain in 20% ethanol | 1 hour |

| 6b. 3% Uranyl Acetate in water | 1 hour |

| 6c. 3% Uranyl Acetate in 20% ethanol | 1 hour |

Dehydration

| 7. 70% ethanol | 5 mins |

| 8. 80% ethanol | 5 mins |

| 9. 90% ethanol | 10 mins |

| 10. 100% ethanol | 3 x 10 mins |

Infiltration

| 11. 'Epon' Resin mix*: 100% ethanol, 1:1 | 1.5 hours |

| 12. 'Epon' Resin mix | 1.5 hours |

Embedding

| 13. In 'Epon' Resin cure at 60°C | Overnight |

Sections cut the following day (when resin not completely hard) and picked up on pioloform copper slot grids. No further staining of sections. For better section quality, embedding should be done for 2 days.

* 'Epon' type resin mix:

- 24g AGR1045 Agar 100 Resin

- 16g AGR1053 DDS (Dodecenyl Succinic Anhydride) EM grade redistilled

- 10g AGR1083 MNA (Methyl Nadic Anhydride) redistilled

- 1.5g AGR1062 BDMA (Benzyl Dimethylamine)

Results

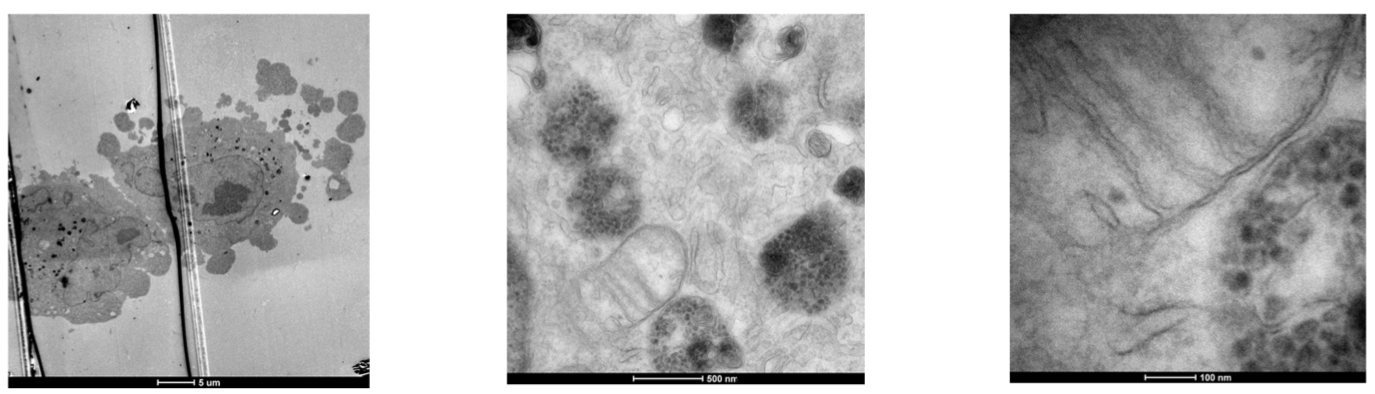

6a) TEM images of sample prepared using UA-Zero EM Stain in 20% ethanol staining solution

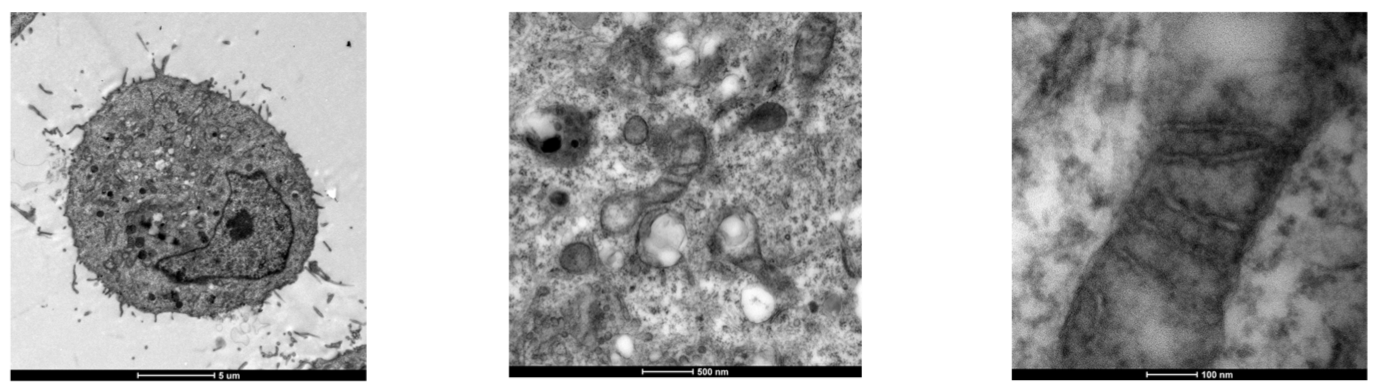

6b) TEM images of sample prepared using 3% Uranyl Acetate in water as staining solution

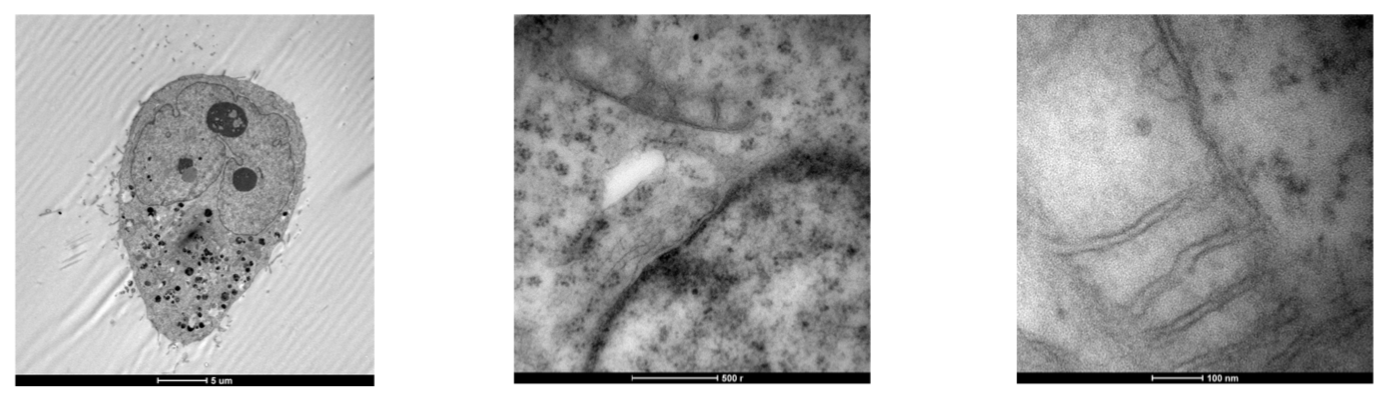

6c) TEM images of sample prepared using 3% Uranyl Acetate in 20% ethanol staining solution