The WELL 3400 Precision Horizontal Diamond Wire Saw

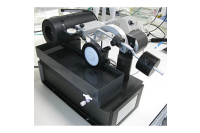

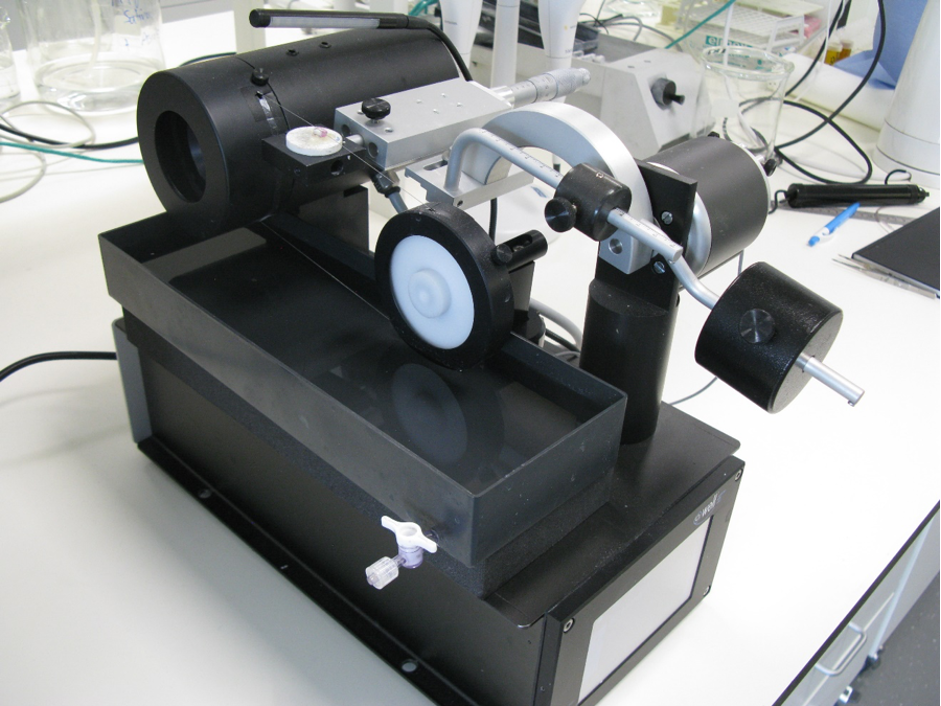

The WELL 3400 Precision Horizontal Diamond Wire Saw achieves smooth, sharp-edged surfaces on virtually any material. The precision cut and resulting smooth finish often reduces or even eliminates the need for polishing if required. The 'cutting tool' is a stainless steel wire with diamonds embedded into the surface using a patented embedding process. This ensures maximum cutting capability and a long wire life, whilst achieving a non-destructive, nondeforming cut and/or slice in both homogeneous and bonded materials.

The WELL Diamond Wire Saw is utilised in a variety of industries, from archaeology to criminology, geology to dentistry. Below, we highlight an example application of the product from Modus Laboratories, a contract research company for the oral industry based in Reading, UK. Here, the product was used to achieve precisely thin and flat wafers of tooth enamel for Transverse Microradiography (TMR) analysis.

Preparation of tooth enamel wafers for Transverse Microradiography (TMR)

Formulations for use in treating or preventing tooth decay in tooth enamel and dentine have been a subject of detailed research since the 18th Century. Since then, modern science has seen many advancements in technology directed towards the investigation of biological systems. In the oral healthcare industry, research on tooth decay and enamel erosion is carried out by highly specialised equipment and techniques. As often is the case, analytical methods used to study and quantify changes in biological materials must be performed with the greatest care to eliminate or to at least recognise the observer effect. The preparation of specimens that are used in an analytical study of biological material, such as tooth enamel, is of fundamental importance to the interpretation of the results.

One example where sample preparation is critical to the results of a study is Transverse Micro Radiography (TMR) and was first reported by Angmar et al in 1963. TMR is an analytical method used to measure the mineral density in tooth enamel or dentine. The general approach is to use a block of enamel a few millimeters wide and 5-10 mm long. The blocks are then subjected to a procedure to form artificial lesions within the enamel block to mimic the condition of caries lesions, the onset of tooth decay. The blocks can then be treated in various ways to investigate the potential of experimental formulations to restore the enamel minerals or even to protect the enamel from the lesion forming.

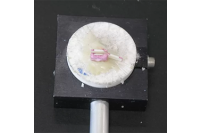

During the treatment the enamel lesions can be analysed by TMR to gain information about changes in mineral density of lesions and so the effectiveness of treatments. The procedure is to section a thin wafer of enamel transversely through the enamel block and lesion. The section is then x-rayed to produce a digital negative which is then computer transformed into a map of the mineral density of the enamel through the lesion. This then gives highly detailed quantitative information about the mineral content in the lesion and surrounding material.

Application of the WELL 3400 Precision Horizontal Diamond Wire Saw in TMR

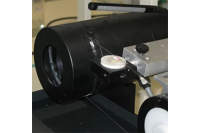

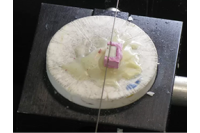

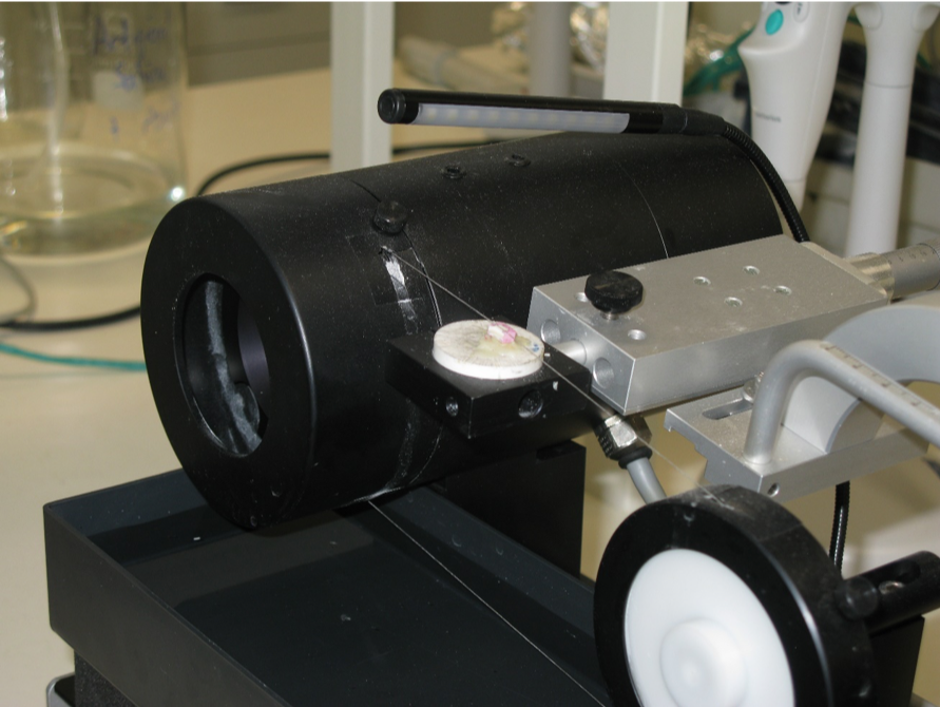

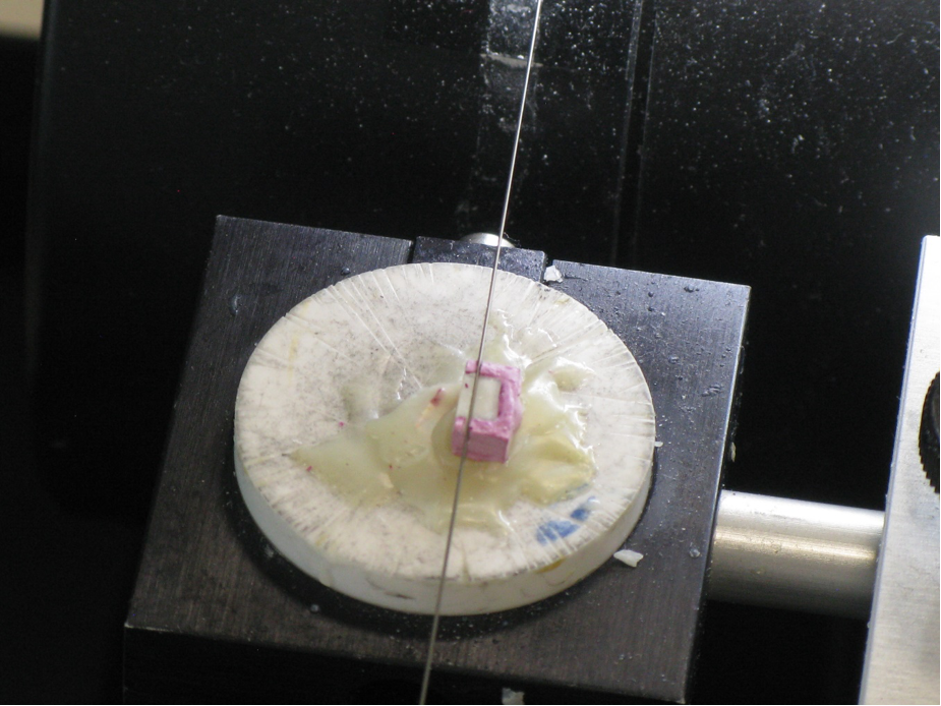

A crucial aspect of TMR analysis is the sectioning of the thin enamel wafers. For precise measurements the wafers are required to be plano-parallel and thin enough to allow x-rays to pass through (80-100um) the sections and to be absorbed quantitatively by the enamel minerals. The wafers are extraordinarily fragile, and the cutting action must be slow and smooth so as not to disturb the lesion. Any changes to the lesion caused by the cutting action may lead to artifacts in the result.

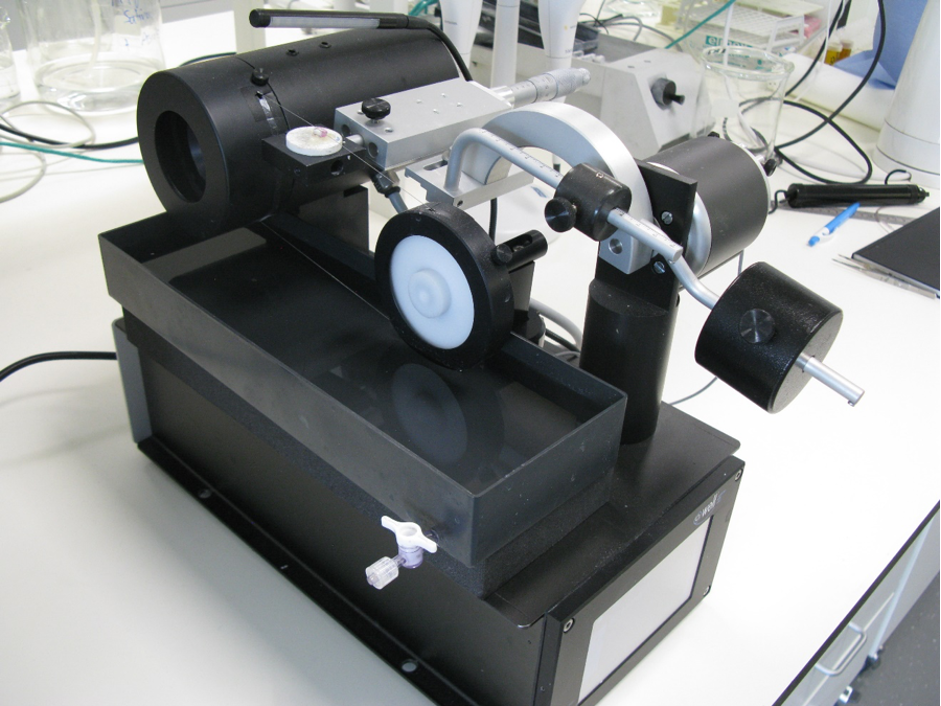

The saw used for cutting wafers at Modus Laboratories is a WELL 3400 Precision Horizontal Diamond Wire Saw with 100um diamond wire, 60g tension and low speed. This gives a perfectly flat cut surface and wafers of high quality for TMR analysis.

If you would like further information, please visit our product page, or contact us:

01279 215506 | [email protected]

Figure 1: The WELL 3400 Precision Horizontal Diamond Wire Saw.

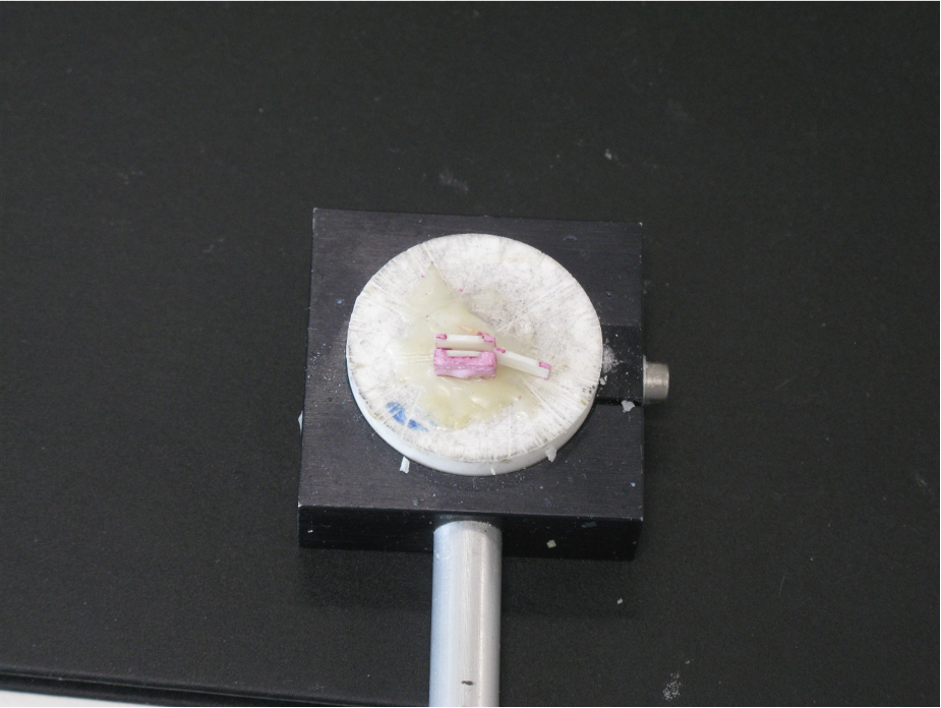

Figure 2: The position of the enamel block on the wire saw.

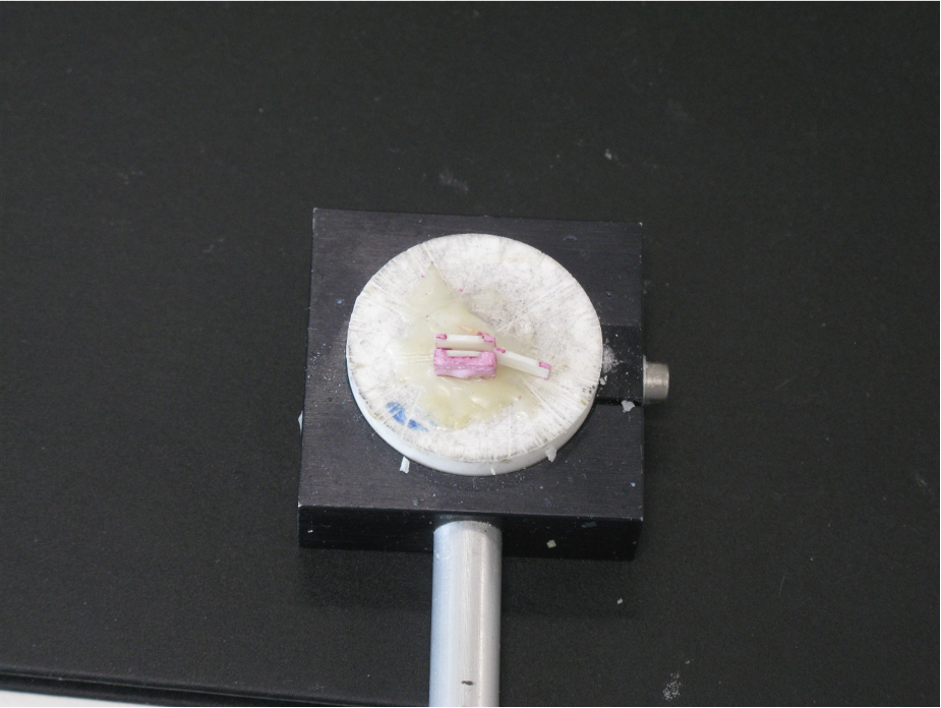

Figure 3: Shows the wire saw cutting the first section through the enamel block.

Figure 4: The diamond wire is moved horizontally by 200um using the Vernier scale, then a second section is made.

Figure 5: The result is a thin wafer section through the enamel lesion and enamel block.

Figure 6: Shows the wafer on its side between the tweezers. The lesion is towards the top of the wafer. The wafer is ready for polishing down to 100um before mounting on a slide for TMR analysis.